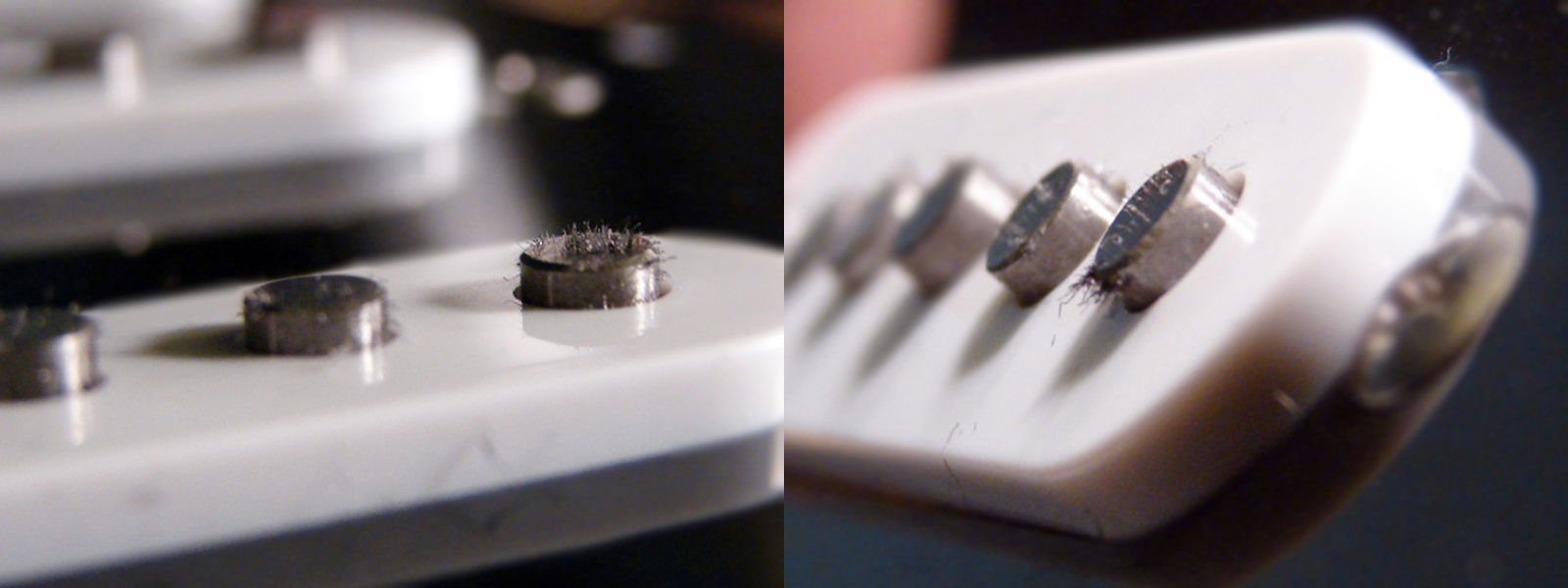

(Author’s note: As steel wool can be so harmful to pickups, we are not willing to risk the integrity of our pickups by allowing steel wool into the shop, even for photographic purposes. Because of this, I have used stock images for illustrative aides.)

I can’t tell you how many times I’ve had to tell our customers that their beloved pickup has gone belly up because of something that was completely avoidable – the usual suspect; STEEL WOOL! In fact, more often than not, they themselves (or even their “reputable guitar tech”) are the ones to blame. Many times when my diagnosis of, “I’m sorry, but your pickup is dead – most likely due to all the steel wool in it. Unfortunately the only way to fix it is to completely re-wind it” solicits a response along the lines of, “How could that even happen? I don’t use steel wool near my pickups.”

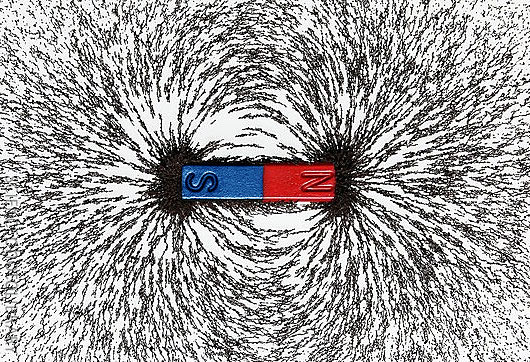

It’s usually safe to assume that the problem originated when they or their guitar tech polished the guitar’s frets. While going to town on the frets, the steel wool will begin to breakdown, sending tiny steel shards and dust all over the instrument and surrounding workspace, which eventually means that it will be attracted to the pickups by their magnetism. (This also means that if your tech did a fret job for someone else last week, there may very well be remnants of steel wool finding its way to your guitar, even though you’re just having your guitar intonated. Sometimes the offending little buggers can even sneak their way into the cavities of the instrument, where it lies in wait indefinitely to wreak havoc on future poor, unsuspecting pickups. Almost as soon as I mention fret polishing, the lightbulb goes off above their heads! “OH! That’s right, I just got a full setup over at (insert big box chain music store here)!” or even, “Well yeah, I mean, I did just get my frets done, but my guy is a pro, he’s been doing this for a long time. I doubt he would do that…” but I can tell you this much; one thing – if not possibly the ONLY thing – that seasoned pros and uninitiated people who have never even seen the underside of a Tele control plate have in common is that far too many of them are totally unaware of the potential damage that steel wool can cause to magnetic guitar pickups. Another defense that I hear pretty often is, “I have been using steel wool around my pickups for ____ years and I’ve never had an issue before.” The short response to this is, “Well, then you’ve been pretty lucky up until now.” though I believe, in legal terms, it’s appropriate to say that admission of guilt probably isn’t the best defense.

The meat and potatoes of the problem lies in the fact that the whole purpose of steel wool is to be hard and abrasive, and though many don’t consider it as such, it is very sharp. It is intended to actually cut though the surface of whatever it is being used on – whether using very coarse or extremely fine steel wool, it works by creating countless little micro-cuts in the surface. Because of its sharp, abrasive nature, as well as the fact that the steel has greater tensile strength than the copper used in the pickup’s coil wire, when steel wool is allowed to get into the pickup, it can impregnate the coil where it is continuously pulled inward toward the magnet, and can actually cut right through the coil wire, thus shorting out the coil or even opening the circuit completely. When this happens, the only recourse is usually to completely rewind the pickup, which can sometimes cost more than the replacement value of many readily available pickups. We test all of our products at several points throughout the build process to all but completely reduce the likelihood of a new pickup leaving our shop with any sort coil failure. So if you ever install a Lollar Pickup (or have it installed for you), only to find that it’s not working as it should, an easy thing to check for is the presence of steel wool – at very least it’s a simple, non-invasive troubleshooting step that you can take before you start ripping the wiring apart. Before installing your new pickups, it’s also a great idea to have a good look inside the guitar cavities to ensure that it doesn’t have a bunch of steel wool hiding down in there, waiting to potentially ruin a perfectly good pickup.

This is not to say that every pickup that comes into contact with steel wool WILL fail, but the chances of failure are definitely increased, so it’s just best to avoid having them in the close proximity altogether. There are many other products available that can substitute for steel wool when polishing frets or doing anything else involving your guitar – abrasive polishing papers, emery cloth, etc. And if, for some reason you or your tech absolutely HAVE TO use steel wool (which, let’s be honest, you don’t really HAVE TO…) precautions should be taken to reduce the likelihood of cross-contamination. Using a good vacuum to clean up between jobs, a can of pressurized air to blow it off of work surfaces, and a healthy dose of painters tape go a long way. I will admit that I was once guilty of using steel wool to polish frets on a guitar or two back in the day, but when I did, I actually covered the entire pickup area with painters tape (usually extending beyond the pickup a good inch or so), then after I was finished, I put another layer of tape on to trap any fragments left behind. Then I blew away all the rest using canned air, and then, after I cleaned up any fragments that I could, I took my guitar away from the work area (and any little steel wool gremlins waiting to jump into my pickups), I removed all the tape in one big piece, keeping any trapped steel wool safely stuck between layers. Was this an overkill in precaution? Perhaps, but at least I’m not worried about steel wool ruining my pickups. Can you say the same?

Richard DeLaine Monks liked this on Facebook.

Eduardo Santos liked this on Facebook.

Michel Sérié liked this on Facebook.

Mike Denallo liked this on Facebook.

Ric Wong liked this on Facebook.